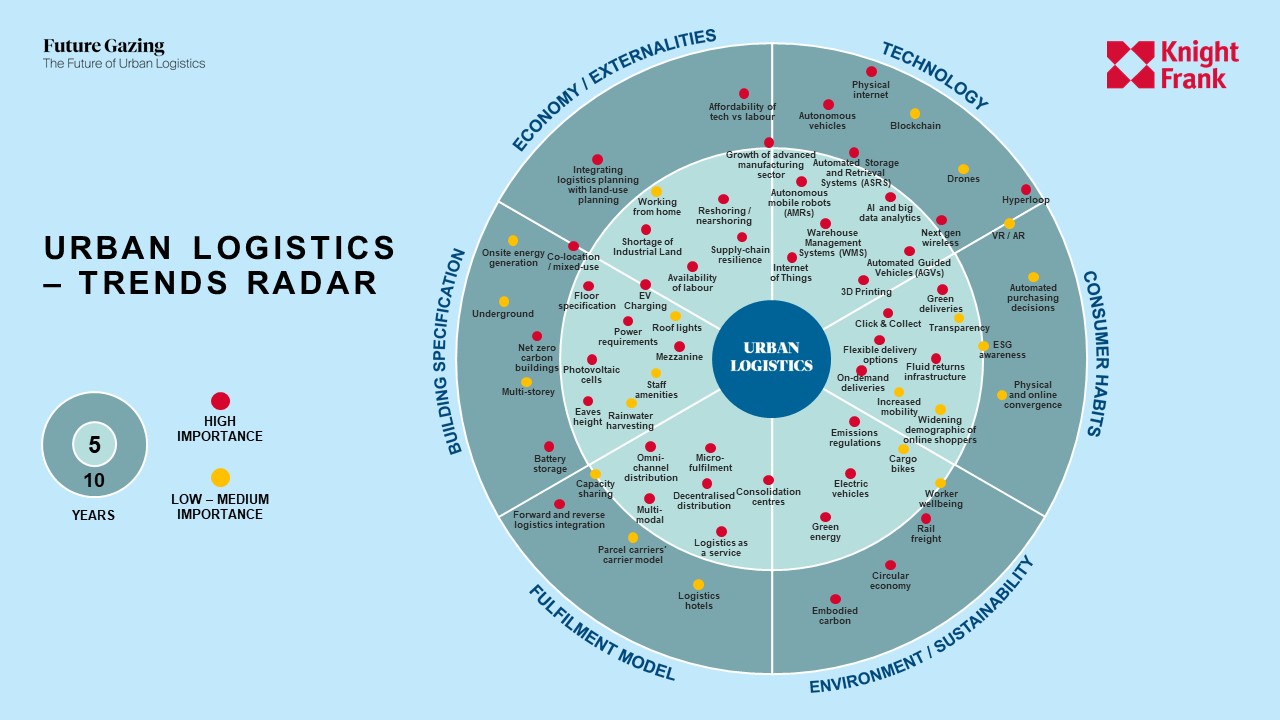

Urban Logistics - Trends Radar

5 minutes to read

Technology

Rapid technological advancements and improving affordability are driving occupiers to adopt robotics solutions for more tasks and across more aspects of the supply chain and enabling the rise of small, highly automated fulfilment centres in urban areas.

The use of Automated Guided Vehicles (AGVs), Autonomous Mobile Robots (AMRs), and Warehouse Management Systems (WMS) will increase as falling costs enable greater adoption. A WMS can utilise IoT (Internet of Things) technology to connect to a variety of communication technologies and automatic identification technologies such as sensors and RFID (Radio Frequency Identification) tags. AGVs may include automated forklift trucks and typically follow magnetic strips, or a track, while AMRs are mobile robots that create their own routes based on information from sensors and will reroute when necessary.

Over the next five years, we anticipate the Internet of Things (IoT) to have far-reaching applications for logistics and warehouse operations. IoT warehouse devices enable items to be scanned, recorded, and monitored in real-time. RFID (Radio Frequency Identification) tags or sensors can be used to track goods at all stages throughout the supply chain and to ensure correct storage conditions.

Artificial Intelligence (AI) and the use of big data analytics stand to improve supply chain efficiency. As technology for collecting, storing, and analysing data improve, the opportunities to gain insight from big data grow. Techniques for analysing big data include machine learning a part of AI. Elements of AI are now regularly used for predictive analytics concerning distribution route planning and consumer demand planning. Some warehouse operations are also being integrated with augmented guidance and robotic systems to scale inventory management.

Amazon recently cut back its Amazon Prime Air drone delivery business in the UK, which launched in 2016, signalling that the technology and regulatory environment may be some way off from enabling drone parcel deliveries.

Read more here

Consumer Habits

In cities, on-demand delivery has become a part of everyday life. The Covid-19 pandemic drove a sharp uptick in demand for grocery deliveries and the on-demand grocery delivery market boomed, with companies such as Weezy, Getir, Zapp and Gorrilas offering delivery times of 15-minutes or less.

Market innovators such as Uber, Amazon and Deliveroo are changing consumer expectations around speed, cost, and convenience. Consumers are increasingly demanding flexible delivery options, with safe places, timed deliveries and update notifications, but the challenge for many online retailers is how to provide this to customers.

Environment / Sustainability

Emissions regulations are having an impact on delivery methods in some UK cities. London recently expanded the ULEZ (Ultra Low Emissions Zone) and other cities across the UK are planning to introduce Clean Air Zones (CAZs). Regulatory changes are encouraging firms to adopt greener fleet vehicles such as Cargo bikes and Electric vehicles. These vehicles have implications for operators’ facility locations and fit-out requirements.

Read more here

Fulfilment Models

New technologies, changing consumer habits, and environmental and sustainability considerations are encouraging new retail and logistics formats and this is driving new fulfilment models in urban areas.

New hyper-local fulfilment models are emerging to meet customers’ demand for fast turnaround times. Micro-fulfilment centres (MFCs) are tiny urban warehouses utilising automated systems to fulfil customer orders quickly and efficiently. By reducing the size and catchment of fulfilment centres, these facilities can be located within densely populated urban areas offering delivery within an hour. By locating close to the customer, they can reduce the timeframe and delivery costs of last-mile delivery.

As pressure to reduce traffic movements within cities grows, there is an increasing appetite for consolidation centres, where deliveries destined for offices or shops in central locations are consolidated off-site and then taken onward into the city in a single delivery.

New multi-modal delivery models are evolving as a response to road congestion and clean air initiatives. DHL launched London’s first riverboat parcel delivery service last year (2020. The shipments are loaded from electric vehicles, travel along the Thames into central London, for delivery on courier bicycles.

Read more here

Building Specification

Advances in technology and sustainability considerations are impacting building specification requirements. For example, as firms adopt more electric fleet vehicles, they will increasingly need EV charging facilities. This will mean greater power requirements. Greater levels of automation or the use of robotics will also mean higher power usage. Operators may not be able to rely on the grid to provide this power, meaning onsite energy generation, this may be done through photovoltaic cells.

Economy / Externalities

New technologies offer cleaner, flexible, scalable solutions and many of the drivers that led to offshoring are no longer applicable. Re-shoring or bringing manufacturing back to the UK, and into urban areas has the benefit of building resilience into supply chains but also enhances their sustainability credentials and enables faster turnaround times for consumers. Covid-19, along with the Suez Canal incident in March and the more recent HGV driver shortages have underscored the importance of supply chain resilience.

Industrial land has been undervalued, and eroded, with other use classes given priority. This has led to a shortage of industrial land, the lack of space and development opportunities is driving strong rental growth for industrial assets across urban areas and this is expected to continue over the coming years.

Advances in technologies such as 3D printing and additive manufacturing are enabling the growth of the advanced manufacturing sector within urban areas. They are changing the ways that we make goods, allowing for efficient small-scale production. Designers can develop and create prototypes extremely quickly and replacement parts can be easily printed and dispatched to consumers.

Read more here

Source: Knight Frank

Click here to enlarge image